Pump groups - a new solution in VTS offer

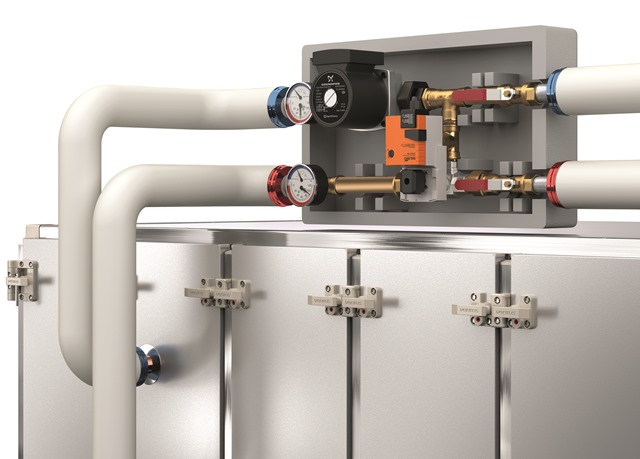

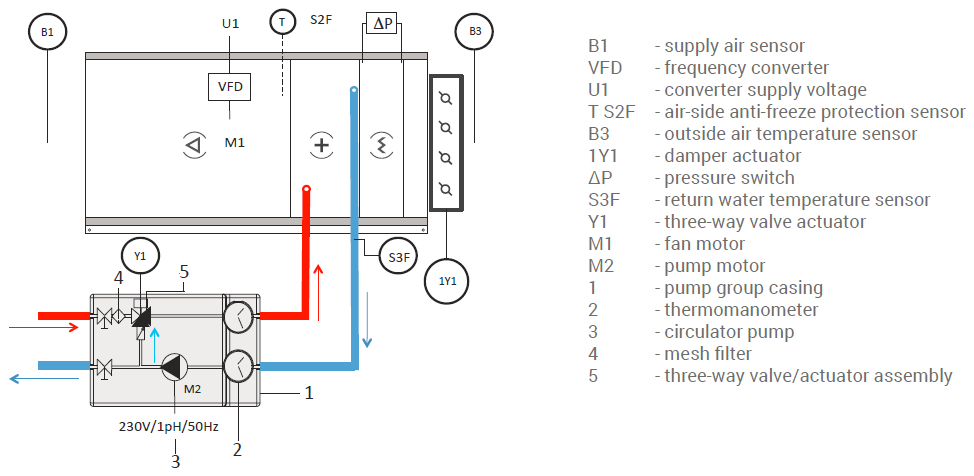

Proper functionality of air handling unit depends equally on its quality and on the quality of external equipment and installations, supporting the central unit and on the way they are attached. One of the key external installations, determining AHU operation, is the process heat installation which supplies water heater with necessary heat volumes. A heating power control system, consisting of a three-valve, a pump and accessories, has to be installed at the site of the water heater connection.

Responding positively to the need of rapid, economical and fault-free connection of this installation, VTS have completed the sales offer of air handling units with pump groups to ensure optimal matching of complete system parameters , responsible for air heating.

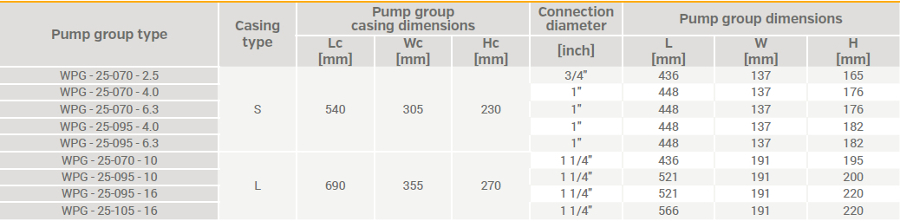

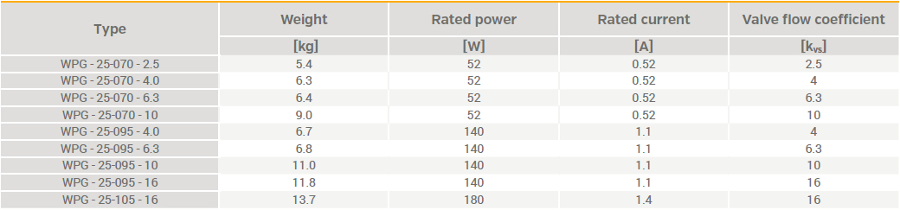

The devices will be included in VTS offer in the beginning of May. 9 types of pump groups will be available, depending on the sensor flow rate and hydraulic resistance (considering the authority of the three-way valve).

|

|

Solution description

Pump centres - are hydraulic systems, housed in a separate enclosure, intended to control the heat power of water heaters of the air, used in air handling units.

|

Operating diagram

Advantages resulting from the use of ready-made pump groups

- Optimal matching of the technical parameters of particular pumping unit and water heater components

- Eliminated errors in connection of particular components of the heater supplying installation

- Easy and user-friendly connection of pump centre to heater and service heat installation

- Guaranteed optimal support of VTS control system and of proper electric matching of the pump protection system

- A possibility to apply double, most effective anti-freeze protection of water, based on return heating medium temperature measurements, active also when the air handling unit is off, and on air temperature control with an anti-freese thermostat. Both protection variants are available in the VTS portfolio of automatic systems.

- Possibility to monitor in real time medium temperatures and pressures on supply and on return from heater

- Easy and intuitive selection of pump centre in a few steps, based on ready characteristics in the operation and maintenance documentation

Structure

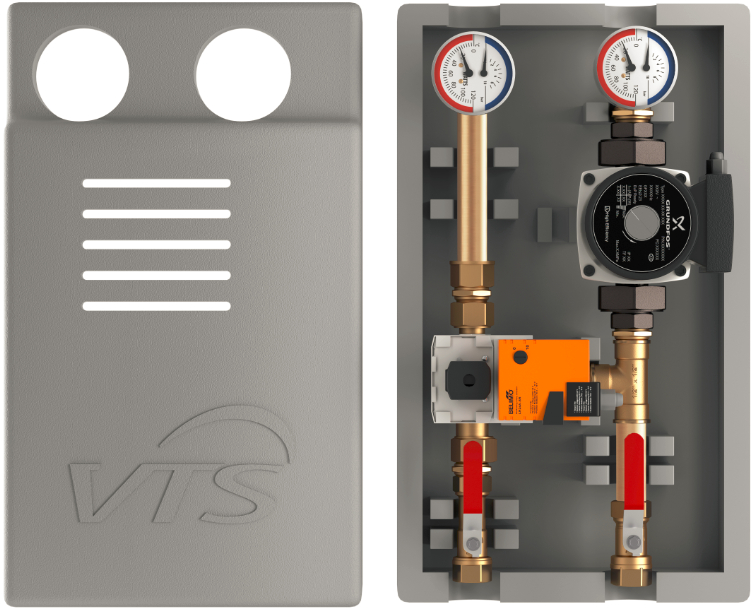

The main pump group components include: circulation water pump, three-way valve with actuator, mesh filter, two thermomanometers. The whole gear is housed in an enclosure of EPP casing which, with its very good insulation parameters, effectively protects against heat loss, while also ensuring protection against mechanical damage and weather conditions.

Key components

|

|

|

PUMP

- 110°C (WPG-25-070) - 95°C (WPG-25-095,WPG-25-105)

- IP 44 (WPG-25-070) - IP X2D (WPG-25-095,WPG-25-105)

|

|

|

Dimensions

|

Pump group parameters

|

Casing

All the pump group have got the same casing, made of EPP.

|

More information is available on-line at: http://vtsgroup.pl/VENTUS/VENTUS2016/en#pump

English

English Polski

Polski Germany

Germany LATAM

LATAM Bulgaria

Bulgaria Estonia

Estonia France

France Hungary

Hungary India

India Italy

Italy Kazakhstan

Kazakhstan Romania

Romania Czech Republic

Czech Republic Ukraine

Ukraine United Arab Emirates

United Arab Emirates Latvia

Latvia Lithuania

Lithuania United States of America

United States of America

Turkey

Turkey